Fashion Supply Chain:

Did you think ever about how your beautiful red floral dress came to your wardrobe from Cotton Field? There are several processes involved in making that happen. The fashion supply chain is all about how clothes & other fashion products are made and brought to stores for people to buy.

As retailers consider supply chain management extremely important, so different types of supply chain analytics have been used in the industry for over ten years.

Function of Supply Chain Analytics:

- Determining product quantities to produce and reorder

- Identifying optimal distribution center locations

- Minimizing transportation costs

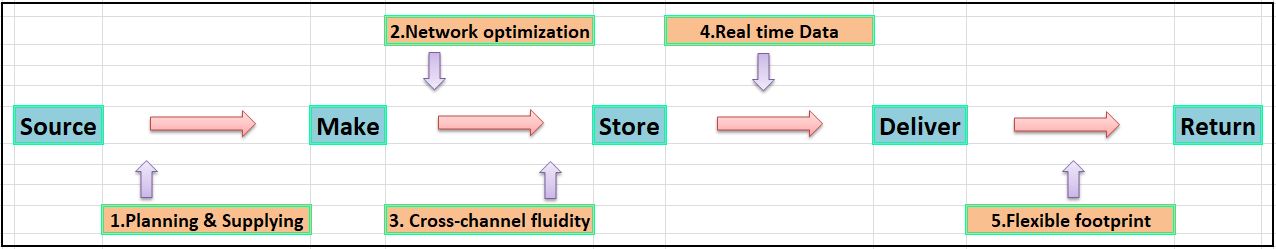

The main supply chain stages are- Source ⇒ Make ⇒ Store ⇒ Deliver ⇒ Return

How Supply Chain Analytics Relate to Fashion:

In the fashion industry, the supply chain is a crucial part of the process to produce & deliver fashion products (i.e.: Clothing, accessories, shoes, etc) to consumers. It makes sense that analytics and fashion are also trends that evolve together. Unfortunately, it was not quick to follow innovation in analytics.

The demand for advanced analytics is increasing now rapidly due to some factors like digitalization of demand, consumer centricity, competition, the emergence of pure online players, and fragmentation of channels.

These tools could enhance both operational efficiency and customer satisfaction.

Main Supply Chain Challenges in Fashion Industry:

01. Lack of synchronized planning and supply: Advancement in this area is particularly necessary as the competitive nature of the fashion industry requires shorter lead times and the flexibility to adapt by consistently introducing new products and collections.

02. Lack of network optimization: Storage & distribution centers require optimization solutions due to the increasing number of both online and physical stores.

03. Lack of Visibility and cross-channel stock fluidity: Retailers frequently talk about the need for better visibility across different channels and smoother movement of stock between them to increase sales turnover and lower inventory costs.

04. Lack of real-time data visibility and integrated demand forecasting: Fashion retailers experiencing fast growth online are facing challenges with efficiency regarding product returns. The rate of returns for items bought online can be as high as 30%, leading to significant costs and impacting potential sales.

05. Limited flexibility in network and distribution footprint: The lack of flexibility in network and distribution footprint makes it hard for decision-makers to choose between keeping costs down and making sure customers are happy. If they don’t balance this well, they could end up making less money in the long run.

Implementing Advanced Analytics in Fashion Industry:

In the past, the optimization of locations, inventory levels, and supply routes were among the earliest analytical approaches in business. These sorts of problems were typically resolved with operations research approaches.

However, some fashion retailers have now started employing predictive models to forecast replenishment times, stockout conditions, and returns. Recently they have shown interest in global, flexible, optimized, and event-driven supply chains while keeping the potential for substitute products in consideration.

Globally retailers are constantly struggling to implement rapid restocking on carryovers and minimize the stock outs which can lead to lost sales.

Let’s look into some trends where data science, together with the availability of data and computational capabilities, is currently driving innovation forward.

Network and localized assortment optimization

Network and localized assortment optimization are two key components of supply chain analytics aimed at improving efficiency, reducing costs, and enhancing customer satisfaction. Let’s delve into each:

Network Optimization: Network optimization involves the strategic design and management of the supply chain network to maximize efficiency and minimize costs. This typically involves decisions regarding the number and location of facilities such as factories, warehouses, distribution centers, and retail stores, as well as the allocation of inventory and transportation resources between these facilities. Key elements of network optimization include:

- Facility Location: Determining the optimal locations for facilities based on factors such as proximity to suppliers and customers, transportation costs, labor availability, and tax considerations.

- Inventory Placement: Deciding where to hold inventory within the network to minimize transportation costs and lead times while ensuring product availability.

- Transportation Routing: Optimizing transportation routes between facilities to minimize costs and transit times.

- Capacity Planning: Balancing capacity constraints across the network to ensure sufficient production and distribution capabilities to meet demand.

- Risk Management: Assessing and mitigating risks such as disruptions in supply or demand, natural disasters, and geopolitical instability.

Advanced analytics techniques such as mathematical optimization, simulation, and predictive modeling are often used to analyze various scenarios and identify the most efficient network configurations.

Localized Assortment Optimization: Localized assortment optimization focuses on tailoring product assortments at individual retail locations to better meet the preferences and demands of local customers. Rather than offering a one-size-fits-all product selection across all stores, retailers analyze local market data to customize assortments for each location. This involves:

- Market Segmentation: Identifying distinct customer segments based on demographic, geographic, behavioral, and psychographic factors.

- Demand Forecasting: Forecasting demand for specific products at each store location based on historical sales data, market trends, seasonality, and promotional activities.

- Assortment Planning: Selecting which products to carry at each store, taking into account demand forecasts, space constraints, inventory levels, and profitability considerations.

- Merchandising Strategies: Implementing merchandising strategies such as product placement, pricing, promotions, and shelf layout to maximize sales and margins.

- Performance Monitoring: Continuously monitoring sales performance and customer feedback to refine assortment strategies over time.

Machine learning algorithms, predictive analytics, and data visualization tools play a crucial role in analyzing large volumes of data and deriving actionable insights to optimize localized assortments.

Order fill Analytics

Imagine you want to buy a white floral dress but you find that it is out of stock. What you will do? you might go to another retailer or wait to restock your required product. Here normally retailers lose customers to their competitors which they don’t want.

Order fill analytics in supply chain analytics refers to the analysis of the percentage of customer orders that are successfully fulfilled within a specified timeframe and according to customer expectations. This metric is critical for assessing supply chain performance and customer satisfaction. Here’s a breakdown of order fill analytics:

Definition of Order Fill Rate: Order fill rate is a measure of how effectively a company fulfills customer orders. It is typically calculated as the ratio of the number of orders successfully filled to the total number of orders received within a specific period. For example, if a company receives 100 customer orders and successfully fulfills 90 of them, the order fill rate would be 90%.

Key Components of Order Fill Analytics:

- Order Processing Time: Analyzing the time it takes from when an order is received to when it is processed and ready for shipment.

- Inventory Accuracy: Assessing the accuracy of inventory data and the availability of products to fulfill orders.

- On-Time Delivery: Evaluating the percentage of orders delivered to customers within the promised or expected timeframe.

- Backorder Rate: Monitoring the rate at which orders cannot be fulfilled due to inventory shortages or other constraints and are placed on backorder.

- Customer Satisfaction: Gathering feedback from customers regarding their order fulfillment experience and satisfaction levels.

Importance of Order Fill Analytics:

- Customer Satisfaction: A high order fill rate indicates that customers are receiving their orders promptly and accurately, leading to increased satisfaction and loyalty.

- Operational Efficiency: Monitoring order fill rates helps identify bottlenecks and inefficiencies in the supply chain, allowing companies to streamline processes and improve performance.

- Revenue Impact: Improving order fill rates can lead to higher sales and revenue by reducing the risk of lost sales due to stockouts or delayed deliveries.

- Cost Reduction: By optimizing order fulfillment processes and inventory management, companies can reduce costs associated with expedited shipping, backorders, and excess inventory.

Analytical Techniques for Order Fill Analytics:

- Data Visualization: Using charts, graphs, and dashboards to visualize order fill rates over time, by product category, customer segment, or geographic region.

- Statistical Analysis: Applying statistical methods to identify trends, patterns, and correlations to fill data and understand the factors influencing performance.

- Predictive Modeling: Building predictive models to forecast future order fill rates based on historical data and external factors such as seasonality, promotions, and market trends.

- Root Cause Analysis: Investigating the root causes of low order fill rates, such as inventory shortages, production delays, transportation issues, or inaccurate demand forecasts.

Application of Supply Chain Analytics

Let’s discuss about some companies who start investing in supply chain analytics.

- Amazon:

- Implemented a new supply chain system based on a non-stationary stochastic model, supporting fulfillment, sourcing, capacity, and inventory decisions.

- Developed the system in-house with a team of supply chain analysts and operations researchers.

- Relies on past data for future predictions in inventory planning, procurement cycles, and purchase orders.

- Known for having one of the most well-tuned supply chain systems globally.

- OfficeMax:

- Implemented new processes and systems for supply chain management focusing on achieving high availability of in-stock items.

- Uses segmented SKU (stock-keeping unit, scannable code) analysis for optimal inventory, transportation cost, and warehouse investment.

- Utilizes differential assortments and fine-tuned restocking frequencies driven by detailed analyses.

- Replenishment model aids in tracking store promotions and their effectiveness.

- Farfetch:

- Operates as a global luxury fashion platform without owning inventory, managing a complex global supply chain.

- Utilizes an intricate supply chain system to offer over 335,000 luxury items from 989 partners to customers in 190 countries.

- The data science team streamlines network optimization and order-filling processes in-house.

- Proactive investment in state-of-the-art structure for achieving operational excellence and gaining a competitive edge.

- Nike:

- Opted to purchase a system instead of building it internally, acquiring Zodiac, a consumer data analytics AI startup in 2018.

- Focuses on reducing out-of-stock rates and managing volatile demand through analytics.

- Acquired Celect, a Boston-based retail analytics company, to assist in integrating new ideas.

- Saved significant time and resources by purchasing pre-built systems rather than developing them in-house.

While some have developed their systems in-house, others have opted to acquire existing solutions, demonstrating the value and importance of analytics in modern supply chain management.

Python Implementation for Supply Chain Analytics:

To understand how we can use the machine learning model for Supply Chain Analytics, please click on the below link

To be updated later….